Authors: Cardoso, L., Bartosik, R., Campabadal, C., de la Torre, D.

National Institute of Agricultural Technologies, Rute 226 km 73,5, Balcarce, (7620) Argentina.

International Grains Program Kansas State University, 1980 Kimball Ave, 102 IGP Bld, Manhattan, KS, (66503) US.

Abstract: The silo-bag is a hermetic storage system used in more than 50 countries. As in any other hermetic storage system, achieving and maintaining a high hermeticity level is a key factor for successful storage.

The air-tightness of the bag can be affected by improper sealing of the end of the bag and perforations in the plastic cover. The evaluation of different sealing techniques and management practices and its effect on the air-tightness level is important for making recommendations for the appropriate use of the silo-bag system.

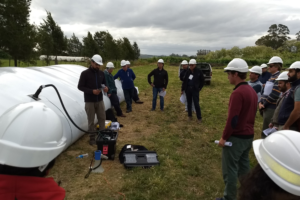

The objective of this study was to perform a pressure decay test to determine the initial air-tightness level of the silo-bag and its evolution after four months of storage in the field.

The pressure decay test was performed in 23 newly made commercial bags holding approximately 200 tonnes of grain each and was repeated in 13 of these bags after 4 months of storage in the field. In addition to the pressure decay test, soil conditions (bag setup on enhanced soil or setup over residues of the crop), sealing system and presence of ruptures were recorded at the beginning and after 4 months of storage.

In general, a low proportion of silo-bag achieved a good initial half pressure decay time (less than 35%), and in 75% of the bags the half pressure decay time decreased after 4 months of storage. Good sealing practices (especially thermo-sealing) and good soil preparation and good care of the plastic bag correlated with higher hermeticity level. Since the visual inspection is not satisfactory for determining the air-tightness level of a given silo-bag, it is recommended to perform a pressure test before a fumigation, controlled or modified atmosphere treatment.